Cabinet Construction

We provide handcrafted and hand-finished custom cabinetry tailored to every detail of your project.

We build to within 1/16 of an inch in our frameless cabinet line and framed cabinet line within an extended stile, eliminating the need for fillers!

Our offerings include Full or Partial Overlay, Inset, and Beaded Inset doors with Face Frame, as well as Frameless construction methods. Our advanced construction techniques allow us to merge multiple small cabinets into a single unit called a gang, ensuring a perfect fit and a seamless installation process depending on access.

Below are the standards included in every cabinet.

All cabinets use Blum hardware for hinges, lifts, and slides. They are all made from CARB II plywood in brown maple (can do other species). We do not use particle board or furniture board for any of our products.

Frameless

Optional Upgrade:

Applied finish ends

Applied End extended to floor Open Toe Kick can be mitered to notched finished end.

Enclosed toe kick on cabinet ends.

Applied Hardwood Panel Finished End

Integrated Hardwood Panel Finished End

Metal, Glass, Wire Mesh instead of Door Panel.

Wall: Depth is 13.5" with plywood adjustable shelves

3/4" Plywood Case - sides, back & deck

Drawer Boxes have 9/16" dovetailed Maple Hardwood sides and 3/8" Plywood bottoms - natural finish is standard.

The interior is stained or painted to match the exterior.

The doors and drawers are attached directly to the cabinet frame, usually with concealed hinges. This design creates a sleek, streamlined look and can maximize interior storage space. Frameless cabinets are also known as European or full access style cabinets.

BASE

WALL

Inset

Doors and drawers fit inside the cabinet face frame openings. The door and drawer fronts sit flush with the frame, creating a smooth, flat surface. These are usually the most expensive option of the three.

Wall: 13 1/4” depth with adjustable shelves.

3/4” solid wood face frame is securely attached with pocket screws and glue.

3/4" Plywood sides and deck

1/4" Plywood Back - With 3/4" nailers at the top and bottom

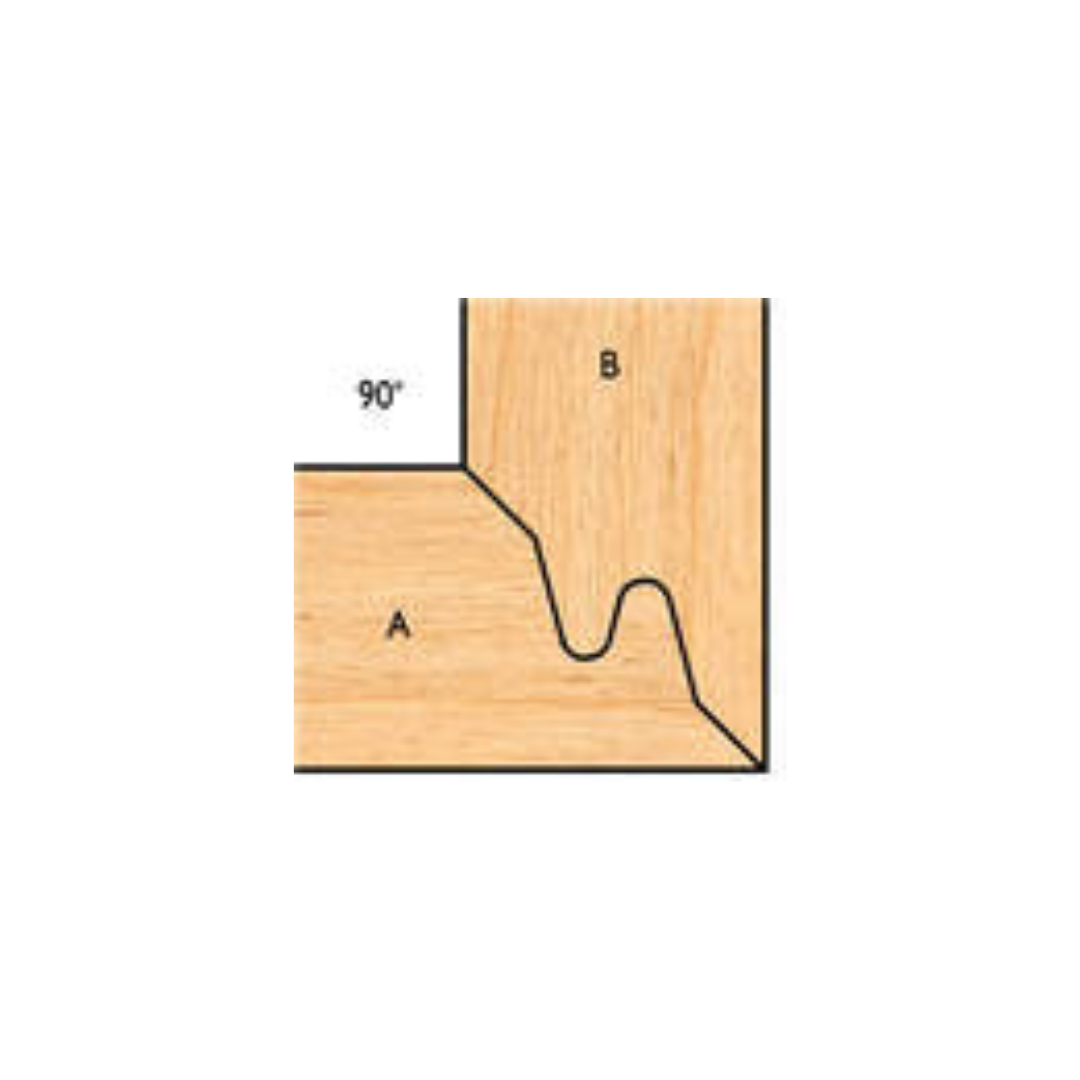

Finish end is Lock Mitred to face frame - see detail image below.

Drawer boxes have 9/16" dovetailed Maple Hardwood sides and 3/8" plywood bottoms - natural finish is standard.

The interior is stained or painted to match the exterior.

Optional Upgrade:

Integrated panel on finish end

Applied finish ends

Applied End extended to floor Open Toe Kick can be mitered to notched finished end.

Enclosed toe kick on cabinet ends.

Integrated Hardwood Panel Finished End

Metal, Glass, Wire Mesh instead of Door Panel.

BASE

WALL

Full Framed

This is the traditional method that most of us are use to. The doors are attached to the front edges of the cabinet box. There are partial and full overlay options. Full overlay, doors and drawers cover the entire face frame, giving a sleek, seamless appearance. Partial overlay, doors (great for matching existing cabinets) and drawers partially cover the face frame, leaving some of the frame visible. Inset doors are described under Inset.

Wall: 13 1/4” depth with adjustable shelves.

3/4” solid wood face frame is securely attached with pocket screws and glue.

3/4" Plywood sides and deck

1/4" Plywood Back - With 3/4" nailers at the top and bottom

1/4” Standard gap between doors and drawers.

Finish end is Lock Mitred to face frame - see detail image below.

Drawer boxes have 9/16" dovetailed Maple Hardwood sides and 3/8" plywood bottoms - natural finish is standard.

The interior is stained or painted to match the exterior.

Optional Upgrade:

Integrated panel on finish end

Applied finish ends

Applied End extended to floor Open Toe Kick can be mitered to notched finished end.

Enclosed toe kick on cabinet ends.

Integrated Hardwood Panel Finished End

Metal, Glass, Wire Mesh instead of Door Panel.